5 Febraury 2026

Importance of CNC Laser Cutting in Modern Fabrication

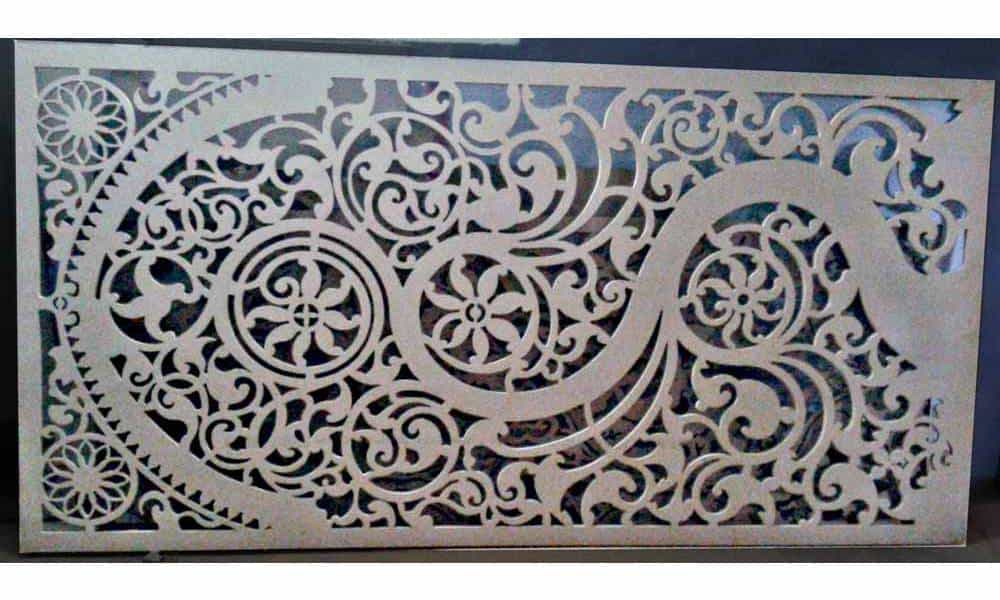

In today’s rapidly evolving manufacturing industry, precision, speed, and consistency play a crucial role in determining product quality and operational efficiency. CNC laser cutting has emerged as one of the most advanced and reliable fabrication technologies, transforming the way metal components are designed and manufactured. By using computer-controlled laser systems, this technology enables highly accurate cutting of metal sheets with exceptional repeatability and minimal margin of error.

What is CNC Laser Cutting?

CNC laser cutting is a computer-controlled cutting process that uses a high-powered laser beam to cut metal sheets with extreme precision. The CNC system follows programmed designs to ensure accurate cuts, smooth edges, and consistent dimensions across all components. This automated process reduces human error and delivers repeatable results, making it ideal for both mass production and custom fabrication projects.

Precision and Accuracy in Fabrication

One of the biggest advantages of CNC laser cutting is its ability to produce highly precise and intricate designs. Clean and sharp edges eliminate the need for extensive finishing work, while accurate dimensions ensure perfect fitment during assembly. This level of precision is especially important for electrical enclosures, servo bodies, cabinet boxes, and automation components where even minor errors can impact performance.

RELATED BLOGS

Insights, updates, and industry knowledge from Jai Vaishno Power Coating Works.

Importance of CNC Laser Cutting in Modern Fabrication

In today’s manufacturing industry, precision and efficiency are critical, and CNC laser cutting has become one of the most reliable fabrication technologies. CNC laser cutting uses advanced computer-controlled systems to cut metal with extreme accuracy, ensuring clean edges and consistent dimensions across every component.

Read More

Why Sheet Metal Fabrication is Essential for Industrial Applications

Sheet metal fabrication plays a vital role in the manufacturing of durable and functional industrial components. From cutting and bending to welding and assembly, sheet metal fabrication enables the production of enclosures, cabinets, and structural parts used across various industries.

Read More

Benefits of Powder Coating for Metal Fabricated Products

Powder coating is a highly effective finishing process that enhances both the durability and appearance of metal products. Unlike traditional painting, powder coating creates a uniform, thick coating that offers superior resistance to corrosion, chemicals, and environmental damage.

Read More